The latest innovation in the China of robot drive axis.

Categories

Contact Us

Tel: 020-83150912

Mob: +86 18998358207

E-mail:fjx18998358207@dqzrobot.cn

Address: Xintai Technology Industrial Park, No. 62 Dachong Road, Nansha District, Guangzhou

3-Axis Gantry Robot

● Logistics and transportation system ● Flexible production line ● Automobile production line ● Truss robot and joint robot mobile platform ● Loading and unloading

Category:

Keywords:

Gantry Truss Manipulator

robot

Description

Technical Parameter

|

project |

Gantry truss parameters |

project |

Gantry truss parameters |

|

Z-axis end load |

50-2900kg |

Acceleration and deceleration time |

1s |

|

Motor model |

Siemens/Inovance |

Linear guides/rectangular guides |

Upper Silver/7th Axis |

|

Reducer model |

Xuanyi/Xinbao/Elite Guangyong/SEW |

Tank e-chain® |

IGUS/Langu/Guoyou |

|

X-axis maximum speed |

1m/s-1.5m/s |

Cylinder/fall arrest |

SMC |

|

Z-axis maximum speed |

0.5m/s |

Repeatability accuracy |

±0.1mm |

|

Y-axis maximum speed |

1m/s-1.5m/s |

Rotating mechanism |

The Z-axis ends with a rotating R-axis |

|

Acceleration a |

0.5-1m/s² |

Number of Y-axes |

1-10 |

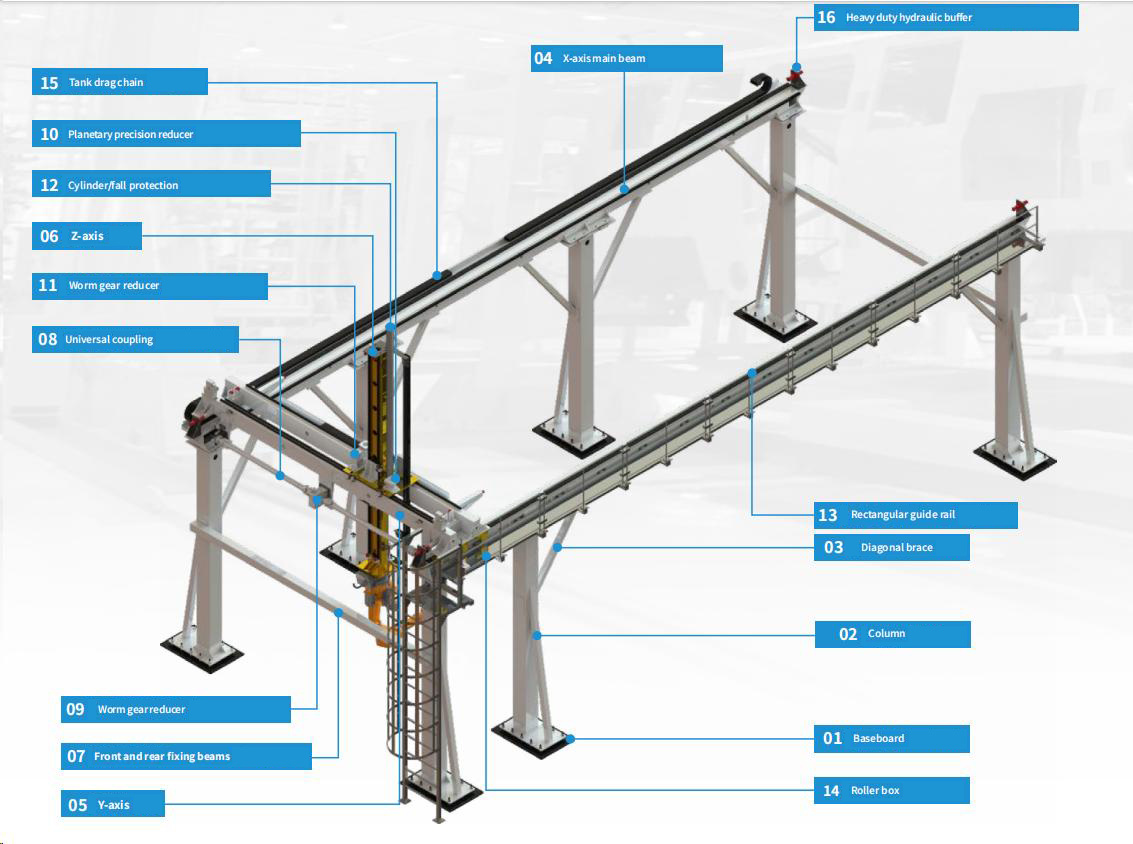

Structural Diagram

Product Introduction:

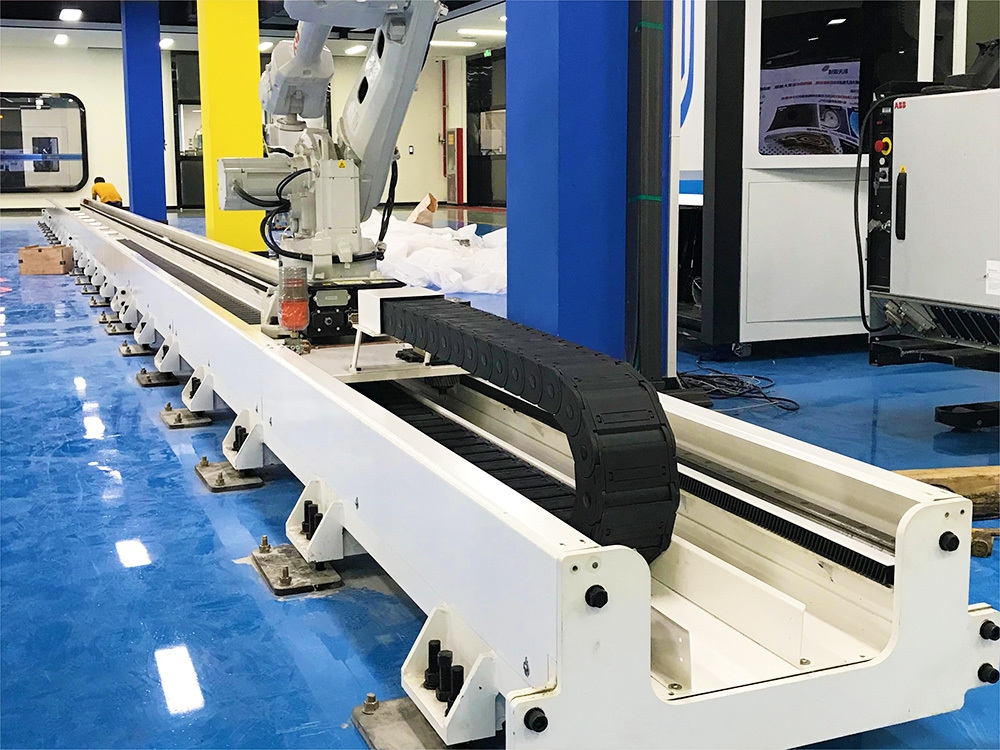

① The seventh axis truss of the robot is a product specifically designed for automated production lines;

② The truss manipulator can be designed for non-standard purposes to meet customer needs;

③ Driven by Siemens servo motors, it is transmitted through precision planetary reducers and high-precision gear racks, with low noise, stable motion, and high repeated positioning accuracy;

④ The movement of the truss manipulator can be controlled separately or connected to on-site equipment to achieve linkage;

⑤ The effective travel range of the truss manipulator is wide, and each position can meet the needs of use. Long travel can be customized;

⑥ Can be used in industries such as handling, machine tool loading and unloading, welding, spraying, etc., with a wide range of usage scenarios;

⑦ The structure is fixed and has undergone finite element analysis and calculation, with short manufacturing cycle, convenient installation, low failure rate, high safety, and easy maintenance.

Application Scenarios:

① Welding applications: various welding methods such as arc welding, resistance welding, laser welding, etc;

② Product Description: The system includes industrial robots, welding equipment, sensing systems, displacement systems, exhaust and dust removal systems, and auxiliary equipment;

③ CNC loading and unloading: the machine tool industry such as shearing machines, bending machines, punching machines, and machining centers, as well as the transportation industry for heavy-duty product processing and assembly;

④ Stacking applications: product stacking and unstacking in various industries such as chemical, household appliances, food, military, etc;

⑤ Spray application: industries such as automotive, digital 3C, ceramics, and furniture processing.

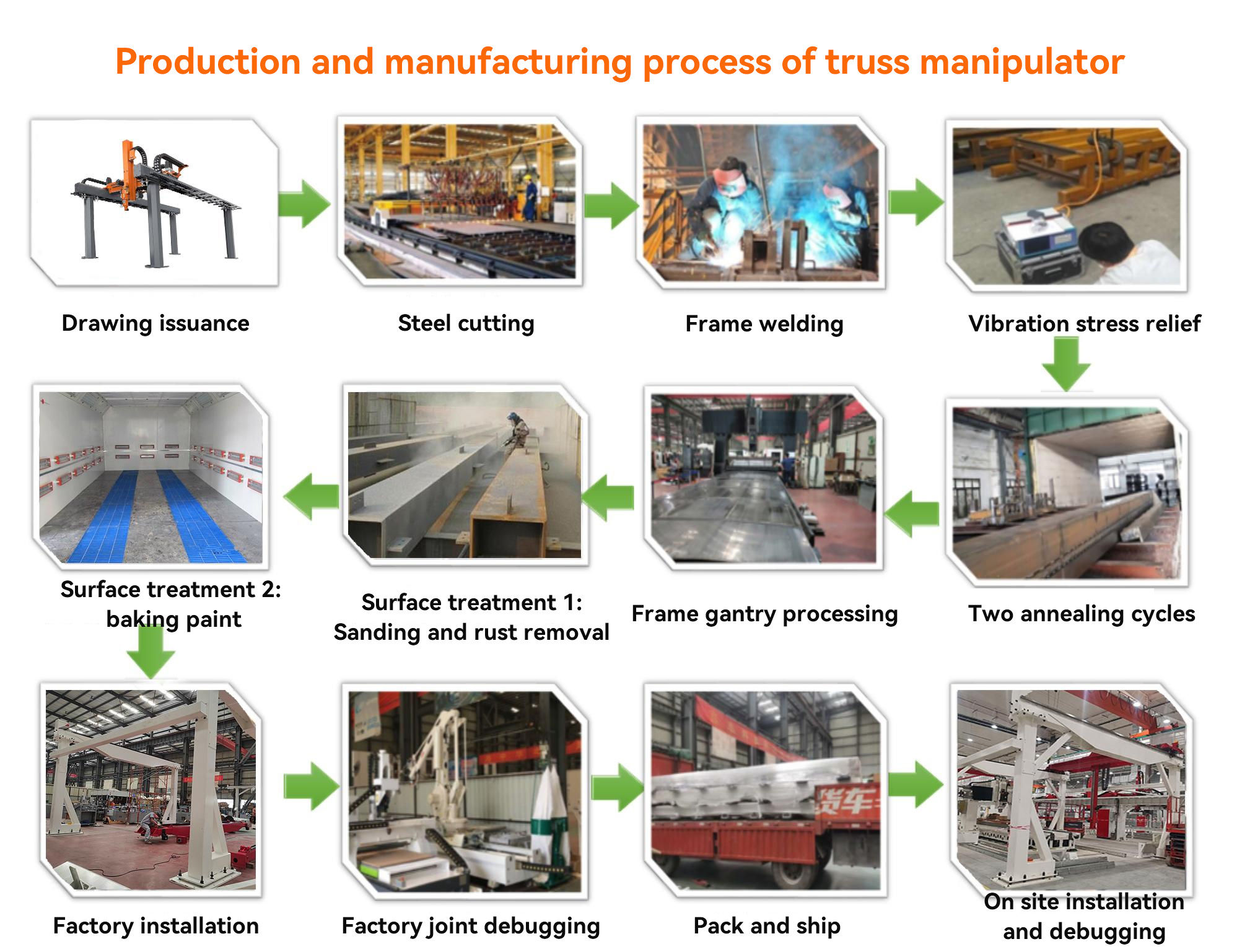

Product Processing Process Diagram:

Keywords: 3-Axis Gantry Robot

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!

Guangzhou Seventh Axis Intelligent Equipment Co., Ltd.

We provide our products with a golden service team, a quick response mechanism, and lifelong follow-up services, so that you can work together without worry.

Xintai Technology Industrial Park, No. 62 Dachong Road, Nansha District, Guangzhou

GET IN TOUCH

Online Message

Guangzhou Seventh Axis Intelligent Equipment Co., Ltd.

Tel: 020-83150912

Mobile phone:+86 18998358207

Email: fjx18998358207@dqzrobot.cn

Address: Xintai Technology Industrial Park, No. 62 Dachong Road, Nansha District, Guangzhou