The latest innovation in the China of robot drive axis.

Latest News

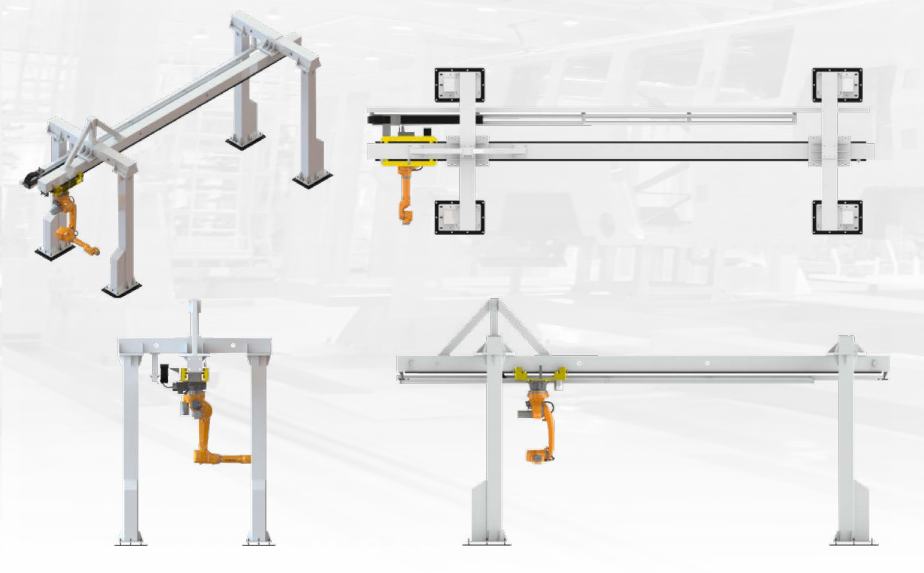

Precision in Motion: Unlocking Industrial Efficiency with Gantry Robot Technology

Release time:

Dec 08,2025

A gantry robot has become one of the most reliable and efficient automation solutions in modern industrial production, offering exceptional flexibility, high payload capacity, and consistent performance across demanding applications.

A gantry robot has become one of the most reliable and efficient automation solutions in modern industrial production, offering exceptional flexibility, high payload capacity, and consistent performance across demanding applications. Built on a rigid overhead framework, a gantry robot moves along multiple axes with outstanding stability and precision, making it ideal for large-scale handling, machining, palletizing, welding, packaging, and assembly environments. As industries continue to pursue higher productivity and smarter automation, the gantry robot stands out as a powerful tool that transforms workflows, reduces operational costs, and boosts output quality.

The core value of a gantry robot lies in its unique structure and unmatched working envelope. Unlike traditional robotic arms that are limited by reach, a gantry robot operates across expansive horizontal and vertical ranges without compromising accuracy. This allows manufacturers to automate tasks over long distances, large workpieces, or wide production lines. Its modular design can be customized to specific application needs, from compact single-beam systems to large multi-axis gantry platforms capable of handling heavy loads with millimeter-level precision.

One of the major advantages of gantry robot systems is their superior stability and repeatability. Built with rigid steel structures, precision linear guides, servo motors, and advanced control systems, they ensure smooth, vibration-free movement even at high speeds. This enhances process accuracy and ensures consistent product quality. The gantry layout also optimizes spatial use by elevating the robot above the workspace, freeing floor area for auxiliary equipment and improving safety by reducing operator interaction with moving mechanics.

Gantry robots play an essential role in solving several pain points commonly faced in industrial automation. Manufacturers often struggle with limited working range, inconsistent manual operations, and high labor costs. A gantry robot addresses these issues by enabling continuous, automated production with minimal human intervention. The ability to integrate seamlessly with conveyors, CNC machines, vision systems, welding torches, and dispensing equipment makes it an all-in-one automation solution capable of supporting a full production workflow. With programmable motion control, it enables rapid changeovers between products, helping businesses adapt to shifting demand without downtime.

Real-world applications demonstrate the broad versatility of gantry robots. In machining centers, they load and unload heavy workpieces with reliable precision, boosting spindle uptime. In sheet metal production, they handle large panels that conventional robots cannot manage. In warehouse and logistics operations, gantry systems support automated palletizing, packaging, and sorting. In automotive manufacturing, they execute high-precision welding and assembly tasks across large frames and chassis. In electronics production, gantry robots are used for PCB handling, adhesive application, and component pick-and-place with extreme accuracy. These examples highlight how gantry robot automation helps industries achieve higher efficiency, stability, and scalability.

Companies also benefit from reduced operational costs when using gantry robots. Their ability to run continuously, maintain high accuracy, and minimize product defects results in substantial long-term savings. The modular design reduces maintenance complexity and allows for easy system upgrades. Their long service life and low failure rate ensure stable production even under heavy-duty use. By integrating gantry robots into existing production systems, businesses gain rapid return on investment through improved throughput, reduced labor requirements, and optimized resource utilization.

In conclusion, a gantry robot is a powerful and versatile automation solution that provides precision, long-range operation, and high load capacity for industrial manufacturers. Its structural advantages, customizable configuration, and compatibility with diverse production processes make it ideal for companies seeking to elevate automation efficiency, reduce labor dependency, and achieve consistent product quality. By investing in gantry robot technology, industries position themselves for smarter, faster, and more sustainable production—meeting modern market demands with confidence and competitiveness.

keywords

Guangzhou Seventh Axis Intelligent Equipment Co., Ltd.

We provide our products with a golden service team, a quick response mechanism, and lifelong follow-up services, so that you can work together without worry.

Xintai Technology Industrial Park, No. 62 Dachong Road, Nansha District, Guangzhou

GET IN TOUCH

Online Message

Guangzhou Seventh Axis Intelligent Equipment Co., Ltd.

Tel: 020-83150912

Mobile phone:+86 18998358207

Email: fjx18998358207@dqzrobot.cn

Address: Xintai Technology Industrial Park, No. 62 Dachong Road, Nansha District, Guangzhou