The latest innovation in the China of robot drive axis.

Latest News

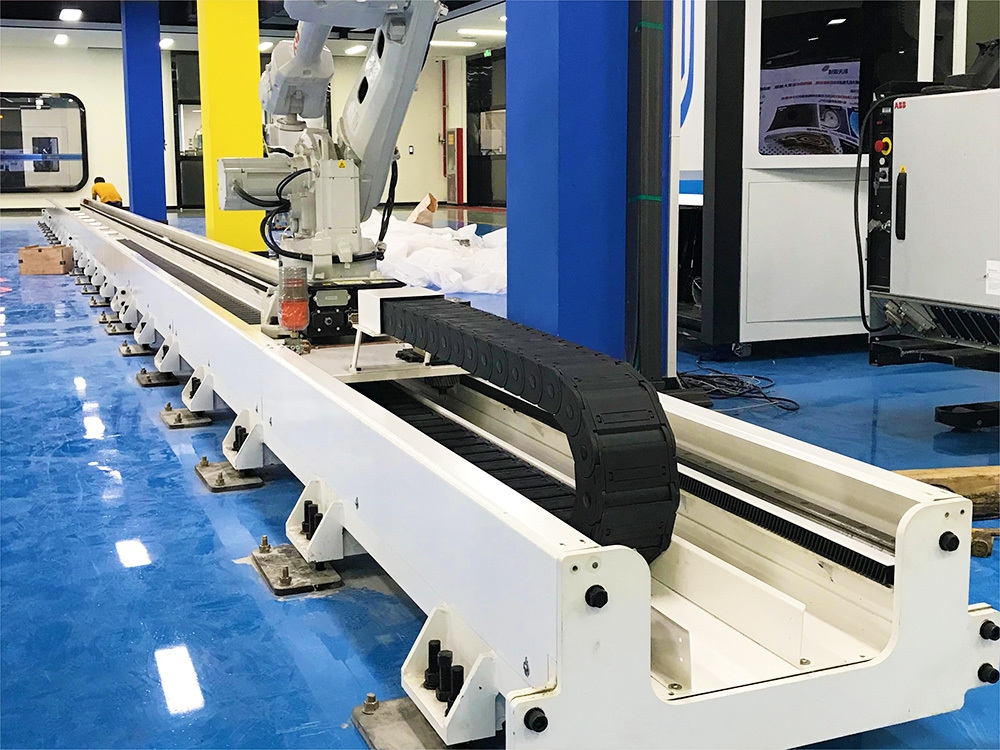

Unlock Precision and Flexibility with Robot Seventh Axis Rail

Release time:

Jan 04,2026

The robot seventh axis rail has revolutionized modern automation, providing industrial robots with extended mobility, precision, and adaptability in complex manufacturing environments

The robot seventh axis rail has revolutionized modern automation, providing industrial robots with extended mobility, precision, and adaptability in complex manufacturing environments. Unlike standard six-axis robots, adding a seventh axis rail enables linear movement along a track, greatly increasing the robot’s working range and efficiency. This technology is ideal for industries such as automotive, aerospace, electronics, and logistics, where large-scale assembly, welding, or material handling is required.

One of the key advantages of the robot seventh axis rail is its ability to optimize production workflows. By extending the robot’s reach, manufacturers can perform multiple tasks across a wider area without repositioning the robot manually. This not only reduces downtime but also improves accuracy and consistency in repetitive processes. Companies integrating a robot seventh axis rail can maximize automation benefits while minimizing human error and operational costs.

Another significant benefit is the flexibility and customization offered by seventh axis systems. These rails can be designed to match specific factory layouts, load capacities, and operational speeds. For example, automotive assembly lines can use long rails for painting or welding operations, while electronics manufacturers may use compact rails for precision component placement. The ability to tailor the rail system ensures seamless integration with existing robotic systems and production lines, enhancing overall efficiency.

Practical applications of the robot seventh axis rail include large-scale assembly, automated welding, machine tending, and material handling. For instance, in automotive production, a seventh axis rail allows a robot to move along the length of a vehicle chassis, completing welding tasks without the need for multiple robots. In logistics, it enables automated pallet handling and transport across extended warehouse areas. Companies deploying this technology experience increased throughput, reduced labor costs, and enhanced production accuracy.

Moreover, the robot seventh axis rail addresses common industrial pain points such as limited workspace, production bottlenecks, and inflexible automation systems. By integrating a linear rail with existing six-axis robots, manufacturers gain expanded coverage and improved workflow efficiency without extensive facility redesigns. This combination of adaptability, precision, and scalability makes the robot seventh axis rail an essential upgrade for modern manufacturing operations.

In conclusion, the robot seventh axis rail provides industries with a powerful tool to enhance robotic mobility, precision, and efficiency. By extending the reach of existing robots, it enables complex, large-scale automation while reducing operational costs and human intervention. Investing in a robot seventh axis rail transforms production lines, offering flexibility, reliability, and measurable improvements in manufacturing performance.

keywords

Previous Page:

Guangzhou Seventh Axis Intelligent Equipment Co., Ltd.

We provide our products with a golden service team, a quick response mechanism, and lifelong follow-up services, so that you can work together without worry.

Xintai Technology Industrial Park, No. 62 Dachong Road, Nansha District, Guangzhou

GET IN TOUCH

Online Message

Guangzhou Seventh Axis Intelligent Equipment Co., Ltd.

Tel: 020-83150912

Mobile phone:+86 18998358207

Email: fjx18998358207@dqzrobot.cn

Address: Xintai Technology Industrial Park, No. 62 Dachong Road, Nansha District, Guangzhou